聯系我們

18560023440

王經理:18560023440

地址:山東省德州市齊河縣經濟開發區齊眾大道7號-2車間

新聞資訊

新聞資訊

激光切割機怎么防止毛刺的產生?

來源:http://www.hbwudeli.com.cn 時間:2019-05-21

毛刺是激光切割加工過程的普遍現象,表如今工件外表過渡處呈現的各種尖角、毛邊等不規則的金屬局部。但是,常見并不代表毛刺的產生能夠被承受,其直接影響加工件的尺寸精度、形位精度和外表粗糙度,降低了產質量量,給后續的檢驗、裝配、運用性能和美觀性帶來了很多問題,所以應該盡量防止毛刺產生。

Burr is a common phenomenon in laser cutting process. It is shown that various irregular metal parts, such as sharp corners and edges, are present at the surface transition of the workpiece. However, the common does not mean that the burr can be sustained. It directly affects the dimensional accuracy, shape and position accuracy and surface roughness of the workpiece, reduces the output and quality, and brings many problems to the follow-up inspection, assembly, application performance and aesthetics. Therefore, the burr should be prevented as far as possible.

激光切割產生毛刺一定是切割機質量問題嗎?

Does the burr produced by laser cutting have to be the quality problem of the cutting machine?

很多企業在運用激光切割機停止切割時,發現切割出來的工件毛刺很多,質量十分不理想,于是就疑心這臺切割機的質量存在問題。真的是這個緣由嗎?其實并不一定。大多數狀況下,毛刺的產生不是由于激光切割機自身存在質量問題,而是由于操作人員錯誤的操作方式或者切割機的頤養、維護不到位形成的。

When many enterprises stop cutting with laser cutting machine, they find that there are many burrs in the cutting workpiece, and the quality is not ideal, so they suspect that the quality of this cutting machine exists problems. Is that really the reason? It's not necessarily true. In most cases, the burr is not caused by the quality problems of the laser cutting machine itself, but by the wrong operation mode of the operator or the inadequate maintenance of the cutting machine.

另外,還有一個產生毛刺的主要緣由,那就是輔助氣體問題。在停止激光切割時,激光束映照到工件外表產生極高的溫度,使工件外表疾速汽化并且蒸發掉,從而完成切割金屬的目的。而輔助氣體的作用就是當工件經過激光束映照氣化后,用來吹掉工件外表殘留的熔渣。假如不這樣做的話,等到熔渣冷卻,就會在工件切割面上構成一層附著的毛刺。

In addition, there is another major cause of burrs, that is, the auxiliary gas problem. When the laser cutting is stopped, the laser beam reflects on the surface of the workpiece to produce extremely high temperature, which makes the surface of the workpiece rapidly vaporize and evaporate, thus completing the purpose of cutting metal. The function of auxiliary gas is to blow off the residual slag on the surface of the workpiece when the workpiece is gasified by laser beam mapping. If not, when the slag is cooled, an adherent burr will be formed on the cutting surface of the workpiece.

下面,我們就來總結一下,幾種常見的毛刺產生緣由,及其相應的處理辦法,協助讀者遠離激光切割毛刺的攪擾。

Next, we will summarize the causes of several common burrs and the corresponding treatment methods to help readers stay away from the disturbance of laser cutting burrs.

激光切割產生毛刺的常見緣由及處理辦法:

Common causes and treatment of burrs in laser cutting:

緣由一:激光切割機產生激光束焦點的上下位置呈現偏向,招致能量沒有恰恰會聚到工件上,工件沒有被充沛汽化,使熔渣產生量增加,不容易吹掉,從而更容易產生毛刺。

Cause: Laser cutting machine produces laser beam focus of the upper and lower position is biased, resulting in energy does not exactly converge on the workpiece, the workpiece is not fully vaporized, so that slag production increased, not easy to blow off, thus easier to produce burrs.

處理辦法:對激光束焦點的位置停止調整,依據其產生的偏移位置,調整到佳狀態。

Processing method: Stop adjusting the position of the focus of laser beam and adjust it to the best state according to the offset position it produces.

緣由二:激光切割機的輸出功率不夠,沒能汽化金屬,從而產生過多的熔渣和毛刺。處理辦法:對激光切割機的工作能否正常狀況停止檢查,假如不正常的話,需求及時修理維護;假如正常的話,還要檢查輸出數值能否正確。

The second reason is that the output power of laser cutting machine is not enough to vaporize metal effectively, resulting in excessive slag and burrs. Solution: To check whether the laser cutting machine can work normally or not, if it is abnormal, it needs to be repaired and maintained in time; if it is normal, it also needs to check whether the output value is correct.

緣由三:激光切割機的切割線速渡過于遲緩,毀壞了切割面的外表質量,產生毛刺。

Reason 3: The cutting speed of laser cutting machine is too slow, which destroys the surface quality of cutting surface and produces burrs.

處理辦法:及時調整并進步切割線速度,使其到達正常的值。

Processing method: timely adjust and improve the cutting line speed, so that it reaches the normal value.

緣由四:激光切割機的輔助氣體純度達不到請求的規范,也會使工件產生毛刺。

Cause 4: The assistant gas purity of laser cutting machine can not meet the required specifications, and it will also cause burrs on the workpiece.

處理辦法:改換純度更高的輔助氣體。

Solution: Replace the auxiliary gas with higher purity.

緣由五:激光切割機工作的時間過長,使設備呈現了不穩定的工作狀態,這樣也會招致毛刺的產生。

Reason 5: Laser cutting machine work too long, so that the equipment presents an unstable working state, which will also lead to burrs.

處理辦法:關閉激光切割機,過一段時間再重新啟并動,使其得到充沛的休息。

Solution: Turn off the laser cutting machine and restart it after a period of time, so that it can get plenty of rest.

以上內容由濟南光纖切割機廠家整理發布,更多相關信息可以點擊我們的官網進行咨詢:http://www.yijuncnc.com

The above content is organized and published by Jinan Fiber Cutting Machine Manufacturer. More relevant information can be consulted by clicking on our official website: http://www.yijuncnc.com.

- 上一篇:怎么做才能達到高質量的切割效果?

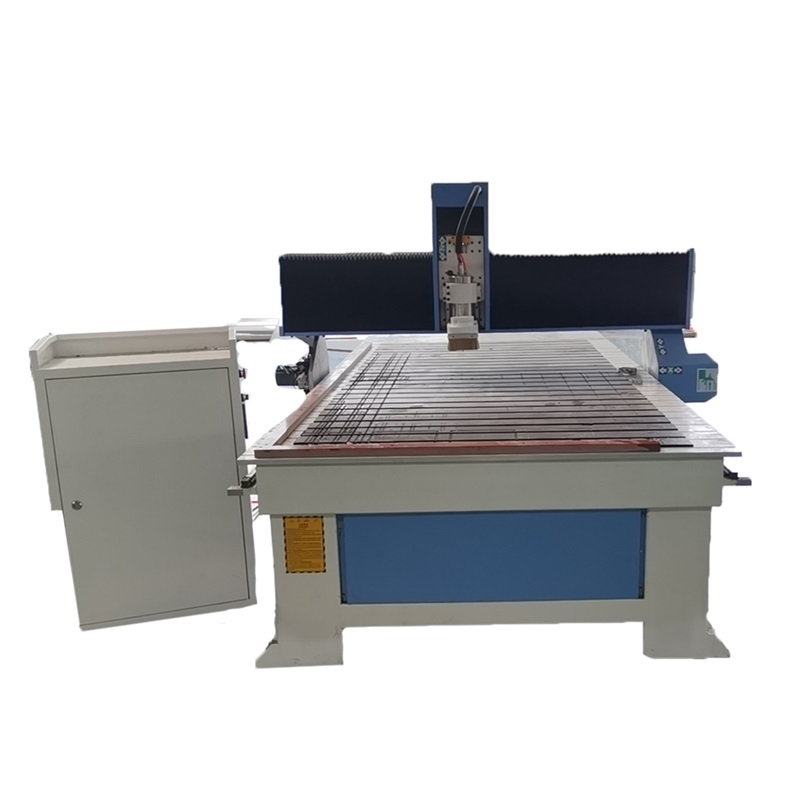

- 下一篇:木工加工比普通木工雕刻機好在哪?